2022 was the first year all 15 VLGCs are on water. How is the fleet doing?

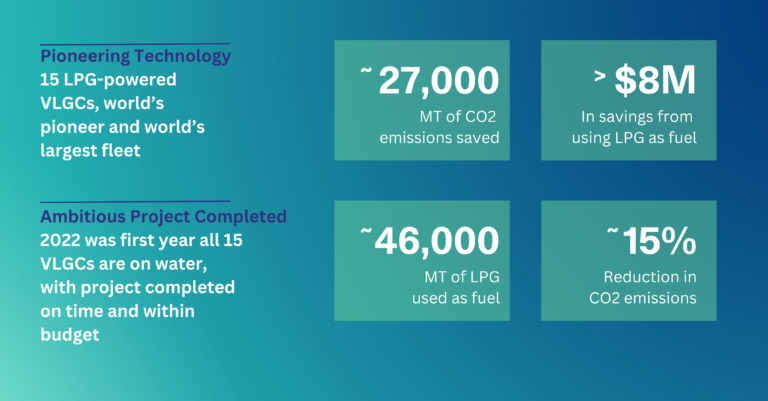

To deliver energy with BW LPG is to ship smarter, more sustainability and more cost-effectively. This is because BW LPG owns and operates the world’s largest fleet of retrofitted Very Large Gas Carriers (VLGCs) with LPG dual-fuel propulsion technology, serving customers with the sector’s lowest emissions profile for long-haul voyages. 2022 was the first year all 15 VLGCs are on water. How is the fleet doing? In short, they have done well from an emissions and cost reduction perspective, and the retrofitting experience has also inspired an innovative approach in the management of LPG coolant (a small quantity of LPG needed to keep cargo tanks at low temperatures) for drydockings of VLGCs powered by compliant fuels.

Reductions in emissions and costs, improvements in operations

We have been systematically scaling up our intake of LPG as fuel, to maximise emissions reduction, and maximise earnings by reducing the cost of fuel. Our engineers are also honing their expertise in dual-fuel engine management. With all 15 LPG-powered VLGCs on water since May 2022, we have been reaping the rewards from our ambitious retrofitting project. In 2022, our 15 LPG-powered vessels bunkered approximately 46,000 metric tons of LPG, saving about US$7.4 million in fuel costs. We also reduced carbon emissions by approximately 27,000 MT by using LPG as fuel. This translated to an approximate 15% reduction in CO2 emissions. We also saw a 99% reduction in SOx emissions, and 10% reduction in NOx emissions. Our LPG deck tanks complement existing fuel oil bunker capacities and provided us with full fuel and cargo flexibility during operations. We also established LPG bunker fuel contracts with new and existing partners in major loading ports.

An innovative approach to managing drydocking operations

And as we enjoy meaningful returns on investment on the sustainability, economic and operational fronts, the retrofitting process also highlighted how experience and innovative thinking can support smart operations. To overcome the challenge of securing terminal schedules for discharging and loading of LPG cargo, fuel and coolant, the Operations team decided to use an established process of ship-to-ship transfer (STS) of LPG cargo, for the STS of LPG as fuel and coolant – the STS of LPG as fuel being a world’s first.

Operationally, there is no difference in conducting STS of LPG as cargo, fuel or coolant. During an STS operation, one vessel, typically the larger vessel, will keep its course, while the other vessel approaches slowly by course alternation. When they are close enough, and mooring lines tightened, STS operation begins.

This initiative to deploy a dedicated vessel to collect, store and re-supply LPG as fuel and coolant has become standard practice for the management of coolant during drydocking of our vessels powered by compliant fuels. Since our first STS operations with BW Balder in May 2021, we have realised multiple benefits from this practice. By having a time-chartered vessel in international waters, we are not restricted by quarantine considerations onshore. In addition, we potentially save on off-hire time, as we do not have to sail to a terminal for loading, nor face challenges related to coolant availability. With less uncertainties in project management, we can provide customers with firmer commitments for their time-chartered vessels to be back in service with a faster turnaround time. Also, as we store and reuse LPG coolant, we can ensure compliance with relevant regulations related to product origins, save on costs to replace coolant, and reduce emissions to the environment.

Overcoming challenges with collaboration and experience

Reflecting on an ambitious project involving pioneering technology, Roy A.M. Hansen, Senior Technical Manager, says “Ensuring we trained our crew and employees to the needed level of competence has been one of our biggest challenges. We were working with new technology on a large scale, and Covid-19 did not help with training arrangements. We had to train remotely and online, and this was something we had not expected during our robust testing stage. We solved this with frequent and open sharing of experience, and using our internal communications platform to cascade information quickly and broadly.”

He adds, “As with all new technology, we had our share of teething challenges. We had to cope with design improvements to the fuel system and components, and our dedicated crew and staff overcame all obstacles with collaboration and innovative thinking – the former is encouraged by our company values, and the latter is possible only because of our deep experience in maritime operations”.

Our fleet of 15 retrofitted LPG-powered is sailing smoothly and making a meaningful impact on our efforts to decarbonise operations, and our capable colleagues onshore and at sea is the reason for our success.

Read More:

- Read about LPG propulsion here.

- Read our Annual Report 2021.

- Read our Sustainability Report 2021.

Keywords: Innovation, LPG, Liquefied Petroleum Gas, Propulsion, Maritime, Process, Safety, Efficiency, ESG, Sustainability